A Practical Guide to Screed Testing: What Do the Experts Say?

A Practical Guide to Screed Testing: What Do the Experts Say?

Optimum drying time for UFH Screeds

Optimum drying time for different types of screeds for under floor heating systems

Optimum drying time for different types of screeds for under floor heating systems

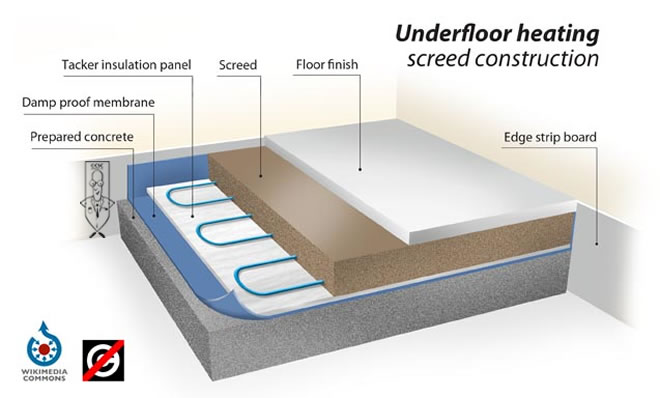

Providing sufficient drying time to screeds is an extremely important aspect that ensures that the screeds lose excessive moisture and is strong enough to withstand the final loads. However, as the drying period can generally be quite long (depending on the type of screed used) it is often seen that due attention is not paid to give screeds the required drying time, and this ultimately is found to be one of the major reasons for the failure of final floor finishes.

It is therefore important to follow the manufacturer’s instruction for the screed, and allow the screed to dry naturally over the prescribed drying period. The various types of screeds used for under floor heating systems include:

Traditional screeds

Traditional screeds- Anhydrite screeds

- Screeds with additives

- Fast drying floor screeds like FlexiDry

Traditional screeds:

This is one of the commonly used screeds for under floor heating systems. Traditional screeds consist of Portland cement and sand mixed in the ratio of 1: 4-5, and typically require up to 121 days to dry optimally. This is considering that an ambient temperature condition of 20ºC is provided. Traditional screeds generally dry at a rate of 1mm/day for the first 40mm, and 0.5 mm thereafter after the screed has been cured for 7 days.

However, it is possible to allow light foot traffic to proceed over the protected screeded surface once the screed has dried for 48 hours.

Anhydrite Screeds:

Synthetic anhydrite is a gypsum-like bye-product of the chemical industry, which when combined with admixtures and aggregates, serves as a very good screed material. Though anhydrite screeds were traditionally hand laid like cementitious screeds, they have recently been developed into flow-applied screeds.

These screeds generally present the advantage, whereby a curing process and surface protection is generally not required. Although protection may be more suitable for expected heavy traffic and point loads but covering the surface will extend the drying period. Consequently these screeds are usually dry and ready for the final floor finish by around 80 days after installation at a depth of 60mm. However, anhydrite screeds also require a minimum waiting period of 48 hours before permitting light foot traffic to proceed.

Screeds with additives:

Modified cementitious screeds are now available, which provide a much faster drying rate than traditional and anhydrite screeds. These screeds are generally found to be ready for the final floor finish within just 30 days of installation.

Fast Drying floor Screeds like FlexiDry:

Fast drying floor screeds like FlexiDry are some of the most popular screed options now commonly in use for under floor heating systems. These screeds provide very low drying periods of up to just 3 days for complete drying, as compared to the 110 days for traditional screeds. These screeds do not require the usual 7-day curing and allows light foot traffic from 12 hours after installation.

Considering such wide variations in the drying time of different screed products, it is extremely important to ensure that the right instructions are followed for the particular screed used. It is also important to bear in mind that it is not advisable to expedite the drying process by turning on the heating system, as it can adversely affect the quality of the screed. If the under floor heating is turned on after four weeks of drying (for traditional screeds), always make sure that it is turned on at a low level, and increased only in a gradual manner.