A Practical Guide to Screed Testing: What Do the Experts Say?

A Practical Guide to Screed Testing: What Do the Experts Say?

Considerations for screed over under floor heating

Things to bear in mind while using a cementitious screed over under floor heating

Things to bear in mind while using a cementitious screed over under floor heating

One of the major issues presented by cementitious screeds for under floor heating systems are – poor compaction around the heating pipes. For under floor heating systems using plastic hot water pipes as the heating elements, poor compaction is often noticed around and beneath the hot water pipes, resulting in inadequate soundness of the screed.

The high shrinkage potential of cementitious screed, coupled with constant temperature variation caused by the heating cycle can further be a reason for cracking and curling of the screed.

It is therefore important to pay attention to the following while going for cementitious screeds for under floor heating systems:

- Ensure a minimum screed thickness of 75mm overall, and 50mm over the heating pipes

- Provide reinforcement either with D49 or D98 mesh over the pipes, as per BS 4483 or Polypropylene fibres with steel reinforcement at day joints.

- The Construction Industry Research and Information Association ( CIRIA) recommends the use of a semi-dry fine concrete with a water reducing admixture to reduce shrinkage problems or a high-workability fine concrete with a super plasticizer to reduce compaction problems

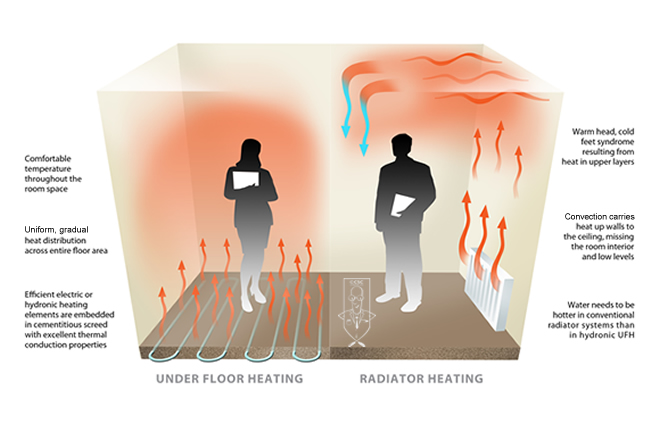

Considering the general problems posed by traditional cementitious screeds, one of the most recommended screeds for use over under floor heating systems are modified screeds like FlexiDry. FlexiDry fast drying floor screeds are found to be ideal for under floor heating systems, as it helps to overcome the general compaction, cracking and curling issues, dimensioanally stable with a consolidated mollecular structure and also improves the energy efficiency of the heating system by acting as an efficient heat conductor.

Considering the general problems posed by traditional cementitious screeds, one of the most recommended screeds for use over under floor heating systems are modified screeds like FlexiDry. FlexiDry fast drying floor screeds are found to be ideal for under floor heating systems, as it helps to overcome the general compaction, cracking and curling issues, dimensioanally stable with a consolidated mollecular structure and also improves the energy efficiency of the heating system by acting as an efficient heat conductor.

Choosing a good screed is an extremely important aspect for under floor heating systems, as the right screed serves as a complementary element that helps UFH systems function at their best.