If you have joined our gang on the Screed Scientist website to learn a thing or two about screeding, well consider yourself lucky in that you might actually know more than our latest recruit ‘The Screed Apprentice’

It occurred to us that we were a bit heavy on the boffin side with The Screed Scientist, The Screed Doctor and The Underfloor Heating Man. Who was actually going to ask the questions? Who was actually going to get on with some real work? Could you see The Screed Doctor coiling up the screed pipes or running around shouting at the MEWP drivers not to crush the screed? No, of course not! The Dr will be too busy taking samples and validating crushing resistance of the aforementioned specimens.

The whole idea for this website was to educate the industry, to ask the obvious questions and not to be afraid to test conventional wisdom in an effort to get the right things done first time…..

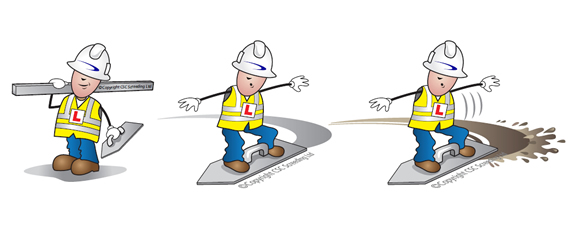

So enter The Screed Apprentice!

Now that the introductions are over, we have some work for him. He needs to get himself over to the CSC Screeding yard to carry out some testing. As you know our whole western civilization is based upon innovation. If you innovate and bring new ideas to market then you can progress, if you don’t, then you risk getting wiped out by those who are prepared to operate in such a manner. Ok, ok, lets forget the lofty discussion on the global economics system and concentrate on pushing the boundaries of floor screeding. Can we take some conventional wisdom and look to gain some efficiencies? Now that is a relevant question and why you are here on our site.

So, back to the young gun:

“Mr The Screed Apprentice, your mission (and you have no ability to refuse this mission due to your status as an apprentice) is to make up some samples at our yard for testing as follows:”

- Make up 8 boxes in timber, using 25mm, 50mm & 75mm Insulation and applying a Isocrete K Screed at 60mm with varying mix designs.

- The purpose is to see what ISCR (in situ crushing resistance) we could achieve and to see if there is an opportunity in the market for thinner screeds achieving greater strength. Could this help a few projects along?

- Will it be possible to achieve Cat A, B & C, which could be applicable for markets in the residential to commercial sectors.

Again back to the whipper snapper and we will let you imagine the next bits…..

- Where’s the start button on this Mortel Meister …..

- Oi you horrible urchin! Hard Hat? Hi-vis jacket? (If he cant get it right on our own site how can we possibly let him lose on a client site?)

- Sorry I forgot to add the K Screed…

- What’s this spinning laser thing used for?

- Oi, which part of “put yer goggles on” did you not understand ….

On a serious note:

While we are having a bit of fun with our new character we could not be more serious in our intentions. Innovation and details are key. If we can get our screed depth down then there are opportunities to add more insulation to improve the building envelopes’ energy efficiency and performance as well as lowering the cost of the deployed screed.

Would you like to know more? Join our newsletter or give us a call and talk to the real Screed Scientist.