A Practical Guide to Screed Testing: What Do the Experts Say?

A Practical Guide to Screed Testing: What Do the Experts Say?

Floor Screeding

The Essential Guide to Floor Screeding

Last updated 03 Feb 2013 ©CSC ScreedingScreeding a floor is the simple act of applying a well blended mixture of Ordinary Portland Cement with graded agregates and water to a floor base, in order to form a sturdy sub-floor that is capable of taking on the final floor finish or act as a final wearing surface. Nonetheless, as simple as this process might sound, there is a lot more to screeding than trowelling on the cement sand mixture. It is one of the most vital steps in flooring that plays a major role in ensuring the quality, finish and durability of the entire flooring.

When a well laid screed can extend the life of a floor and do wonders to its quality, a failed screed can drastically affect the quality of the floor and could be an immensely expensive issue with drastic measures being essential to revive it to an acceptable condition.

In an initiative to share knowledge with the industry and to help curb the screed failure numbers that are on the rise, CSC Screeding with the help of the ‘Screed Scientist’ has compiled an Essential Floor Screeding Guide, to guide you through the steps of getting this simple act right.

Five essential steps to get your floor screeding right:

- The right floor screeding contractor

- The right floor screed

- The right screed mix

- The right process for installing the screed

- The right measures for screed protection

The Right Floor Screeding Contractor

The right screeding contractor would hold extensive experience, a skilled work force and modern equipments, be up to date with the latest technology and have strong references to back up their claims. The more the experience, the better adept the screeder will be in managing the nuances of screeding- all the way through planning, choice of screed , mix design, screed laying and screed protection to delivering on time and within the agreed budget.

The Right Floor Screeding

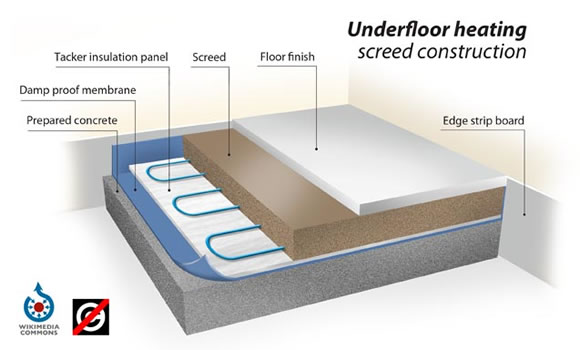

With the different kind of screed types, screed constructions and screed brands available, it could be a laborious task to arrive at a decision quickly. It is important to consider what each type has to offer and how well it fits in with your requirement and make an informed choice.

- Traditional screed: The standard screed mix of cement and sand mixed in the ratio of 1:3-5 is used for creating a defined layer for installing the final floor finish such as tiles, wood, linoleum, vinyl etc. Traditional screeds are generally suitable for use in hospitals, schools, hospitals, retail, homes etc.

- Free flowing screeds: The anhydrite free flowing, self-leveling and self compacting screeds present the major advantage of easy placement and provide reliable results. However, the anhydrite screeds are not suitable for areas that are prone to getting wet. They cannot be used as a final wearing surface and are not compatible with cementitious products.

Floor levelling compounds: These compounds vary from the general screedsin that they are used for levelling or as the final layer of screed to increase the tolerance while laying the floor finishes such as tiles, vinyl etc. They are generally expensive and are used for screeding in warehouses and areas which require a very high level of surface regularity or flatness.

Floor levelling compounds: These compounds vary from the general screedsin that they are used for levelling or as the final layer of screed to increase the tolerance while laying the floor finishes such as tiles, vinyl etc. They are generally expensive and are used for screeding in warehouses and areas which require a very high level of surface regularity or flatness.- Structural Screeds: This type of screed suitable for installing on precast floor surfaces. It is important to seek accurate specifications and calculations from a structural engineer before the installation of structural screeds as the information is vital to decide on the load requirements, flexural strength, bending moment, point loadings, etc.

- Fast drying floor screeds/Accelerated Screeds: If your project is on a strict time line and you do not have the time to wait for the industry benchmark of 1mm per day and 0.5mm thereafter (110 days for 75mm) for the screed to dry, it would be best to go for fast drying floor screeds like FlexiDry which allows you to go for the installation of the final floor finish as early as 3 days after screeding.

The Right Screeding Mix

The Right Screeding Mix

The right screed mix is one that is homogenously blended in the right proportion, following the agreed mix design. When there is the option to choose between ready mix and site mixing of screeds, it is important to consider the viability of each option depending on the location and available space at the work site.

Site mixing of screed is a very efficient and economic way of screed mixing and is suitable for most projects, provided the screed is force action mixed and the work is handled by a skilled work force. The three methods that are generally followed by screeders for site mixing of screeds are:

- Hand Mixing: This is suitable only for very small areas and is not recommended for bigger projects, as the work is strenuous and the estimated quantities and manual errors while mixing can seriously affect the quality of the screed.

- Free Fall Mixers: Free fall mixers are sometimes used by screeders for mixing larger quantities of screed at the work site. When these are sufficient for mixing general concrete mixes and mortar which are of a fluid consistency, screeds mixed using free fall mixers are often found to be of poor quality, weak and crush easily under impact.

- Forced Action Mixers: Forced action mixing is the most efficient and economic method for producing high quality screed mixes on site. Forced action mixing blends the cement and mix homogeneously and is ideal when additives or admixtures are to be added. Forced action mixers are usually of two types:

i) Screed Pumps: These are generally used for forced action mixing of large quantities of screed at the work site.

ii) Pan mixers: These are portable forced action mixers which are ideal for producing high quality screed mix at work sites where the use of bigger equipments is difficult.

Ready Mix Screeds are a good option for work sites where the storage of materials is difficult. But there is always the drawback of heavy traffic posing as a hurdle in getting the screed at the site on time, and might result in a considerable amount of wastage and economic loss.

The Right Process for Installing the Screed

The Right Process for Installing the Screed

It is important to carry out the process of screed installation in a systematic manner to achieve the best results. There are several steps to be followed while preparing to install the screed:

- Check the specification is fit for purpose

- Make sure the substrate is ready to receive the screed.

- Check the access and egress is suitable for screed installation, plant and materials.

- Check the building is watertight.

- Check the datum levels, record the measurement down to finished screed level to ensure minimum and maximum depths are achievable and compliant with tendered nominal allowance.

- Check that running potable water is available at an adjacent point of the material location.

- Check that a waste facility is adjacent to the working areas.

- Check the mixing plant is safe and suitable to use.

- Mix the screed in the correct proportion.

- Apply the screed in a sequential manner, avoiding dry joints.

- Apply trowel cuts where necessary for crack control.

- Keep the working area tidy.

The Right Screeding Protection Measures

The Right Screeding Protection Measures

The last step in screeding – but this is definitely not the least important of the lot. Appropriate screed protection measures right after screed installation until the laying of the final floor finish is an extremely important step in preventing screeding failures, and is of utmost importance in achieving a screed of high quality, finish and durability. From the regulation of site traffic to covering the screeded surface with screed protectors, there are several measures to be considered for protecting the screed. At a basic level, it is imperative to ensure that:

- No site traffic is allowed at least for 24-48 hours after the installation of the screed

- Heavy site traffic is regulated until the installation of the final finish

- Heavy weights are not loaded unless after the consultation with a structural engineer

For more information on screed protection please visit our screed protection website or call us at 0845 500 4055.

Getting your screed right is not difficult. But it is quite easy to get it all wrong unless carried out with attention to the minor details. For any queries regarding your screed or for assistance in choosing your screeds, please feel free to contact us at 0845 500 4055 or info@cscscreeding.co.uk

2013 Latest updates: