The key to the successful implementation of a bonded application is to achieve a good bond between the substrate and the applied bonding coat. Proper preparation is the most important factor for achieving a successful floor screeding installation. Whatever topping or levelling screed is used to achieve the definitive floor level, it will only be as good and as strong as the surface to which it is bonded. It is therefore recommended that the surface be of sound integrity, clean and free of oil, grease, wax, dirt, dust, asphalt, adhesive compounds, paint, gypsum, paint and any other contaminants which might cause detrimental effects to the bond.

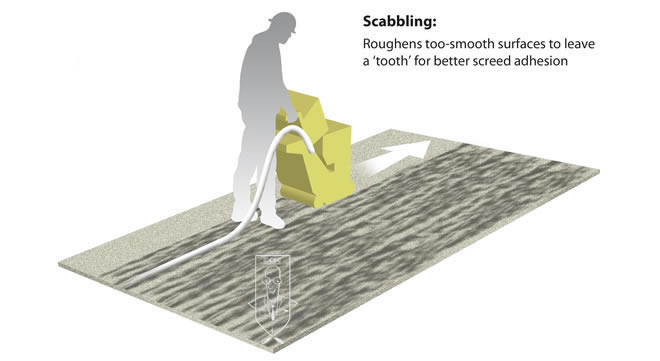

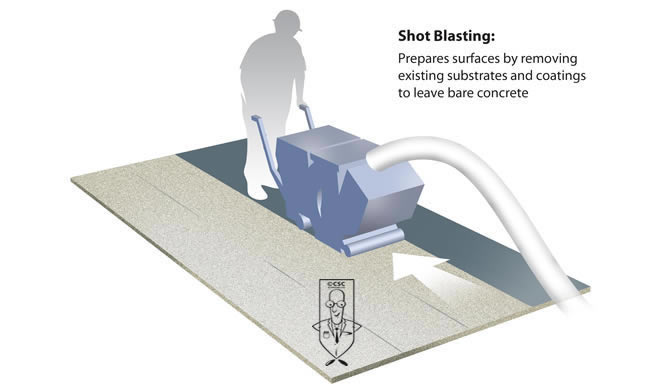

There are numerous ways to prepare the substrate and its surface condition to ensure the required effect. Short cuts and insufficient preparation will cause failures in the levelling and topping screeds. Failure to prepare properly will cause problems further down the line and could cause a huge amount of disruption and financial claims. There are methods such as shot blasting, floor planning, scabbling, grinding, etc. which is variable on the size of the job and the condition of the substrate.

There are numerous ways to prepare the substrate and its surface condition to ensure the required effect. Short cuts and insufficient preparation will cause failures in the levelling and topping screeds. Failure to prepare properly will cause problems further down the line and could cause a huge amount of disruption and financial claims. There are methods such as shot blasting, floor planning, scabbling, grinding, etc. which is variable on the size of the job and the condition of the substrate.

New concrete should be more than six weeks old as shrinkage cracks can occur in the slab and reflect through the levelling screed or topping. Cracks in the concrete would need to be repaired with an appropriate method. Primers should be applied to a completely dry surface to assure a proper bond and consideration should be given to the moisture content of the slab. The moisture content of the slab could migrate to the screed / topping and give rise to a longer dry time. Refer to manufacturers details if specialist toppings / screeds are to be applied. Where the moisture content exceeds recommendations then a surface damp proof membrane can be applied. Care must taken if forced drying of concrete slab as carbonation can take place. Carbonation is where heaters that use fossil fuel cause a combination of Carbon Dioxide mixed with calcium hydroxide in fresh concrete which causes a weak layer of calcium carbonate on the surface. This is known as carbonation and needs to be removed by way of scabbling, planing or shot blasting. Curing compounds that can be applied to concrete surfaces are also detrimental to successful implementation of screeds / toppings and must be completely removed.

New concrete should be more than six weeks old as shrinkage cracks can occur in the slab and reflect through the levelling screed or topping. Cracks in the concrete would need to be repaired with an appropriate method. Primers should be applied to a completely dry surface to assure a proper bond and consideration should be given to the moisture content of the slab. The moisture content of the slab could migrate to the screed / topping and give rise to a longer dry time. Refer to manufacturers details if specialist toppings / screeds are to be applied. Where the moisture content exceeds recommendations then a surface damp proof membrane can be applied. Care must taken if forced drying of concrete slab as carbonation can take place. Carbonation is where heaters that use fossil fuel cause a combination of Carbon Dioxide mixed with calcium hydroxide in fresh concrete which causes a weak layer of calcium carbonate on the surface. This is known as carbonation and needs to be removed by way of scabbling, planing or shot blasting. Curing compounds that can be applied to concrete surfaces are also detrimental to successful implementation of screeds / toppings and must be completely removed.

Old concrete needs the same attention as above and moisture testing should still be carried out as damp problems could exist.