At first glance, relative humidity (RH) is a quite confusing topic. Since people use different terms such as moisture, vapour, water content, relative humidity, absolute humidity, actual humidity, specific humidity or just humidity to indicate how moist the air is, many of them feel confused when they come across the term “relative humidity”. In response to the questions I have received over the years, I decided to write an article that clears up the confusion surrounding relative humidity. Knowing exactly what RH is will allow people to better understand its effects on screed performance.

As the name implies, RH is just a relative value. To find out the actual humidity, RH must be considered in relation to the dew point temperature (the temperature at which the air is saturated with water vapour), wet bulb temperature (the lowest temperature that can be obtained by evaporating water into the air) and dry bulb temperature (the actual temperature of the air measured with a regular air thermometer), and compared with the maximum amount of water vapour the air could hold.

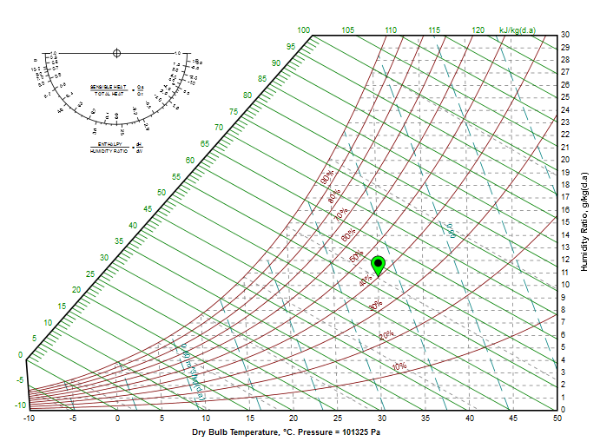

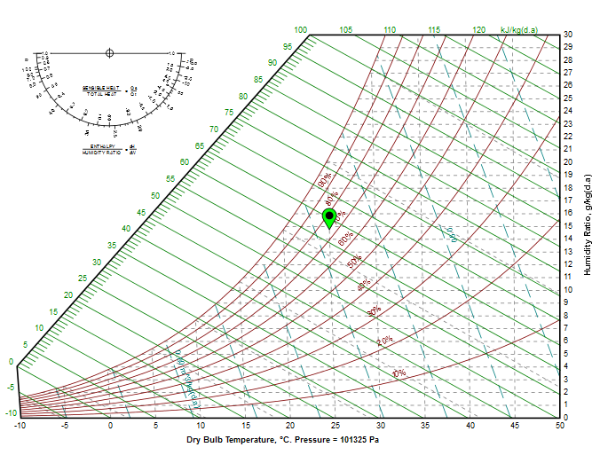

RH needs to be correlated with the air temperature because the moisture holding capability of the air varies with the temperature. For example, if the dry bulb temperature is 30°C and the dew point temperature is 15°C, RH will be 40 percent. If the dry bulb temperature is 25°C and the dew point temperature is 20°C, RH will rise to 70 percent, as shown by the psychrometric charts below.

RH 40%

RH 70%

Because humidity affects not only the properties of the air but also the characteristics of the materials that come in contact with the damp air, understanding the impact of RH on screeds is very important.

The water from the screed is evaporated into the air and transported by air currents. When the screed is laid in cold, damp weather or in confined spaces with poor ventilation, the air above it will stagnate and become saturated with water vapour. In this case, the screed will need more time to dry. One way to reduce the drying time is to ensure adequate ventilation and temperature. A higher rate of air flow will make possible a continuous exchange of moist air with dry air, accelerating the drying process. In addition, heating the screeded area will help increase the moisture absorption capacity of the air, reducing the drying time considerably.

The drying time depends not only on RH, ventilation and temperature but also on the type of screed. When traditional screeds are used, correct drying implies curing with polyethylene sheets to prevent water from dissipating too quickly from the surface and avoid cracking and curling. Conversely, proprietary screed formulations incorporate special additives that allow the water molecules to bond and the screeds to develop adequate strength and dry when the ambient conditions are not ideal.

High RH levels that may prevent the screed from drying optimally within the time frame specified require particular attention. When sensitive decorative treatments (e.g. vinyl tiles, hardwood floors, etc.) are installed onto damp screed, floor failure may occur. Therefore, ensuring that the screed is dry and ready to take on the final floor finish is critically important before proceeding with the installation of the final floor.

There are two methods professionals use to assess moisture content in screeds:

1. Tramex Meter

A Tramex meter provides a very convenient and fast method to measure the moisture content, but the results should only be used as guidance. Since the meter assesses the moisture only at the surface, the screed could be drier or wetter at the top than at the bottom.

2. Calcium Carbide Test

The Calcium Carbide Test is the most accurate method to assess moisture levels in screeds. Implying the use of a screed sample, this test allows specialists to calculate the actual moisture content along with the time the screed needs to dry completely.

*Recommended Moisture Levels According to the Screed Type

| % Moisture | ||

| Not Heated | Heated | |

| Cement-Based Screed | < 2 | < 1.8 |

| Anhydrite Screed | < 0.8 | < 0.5 |

In conclusion, all screeds should be allowed to dry for the specified time frame, irrespective of the screed formulation used. If RH levels are higher than 50 percent or the temperature is lower than 20°C, the drying time should be extended accordingly. In addition, carrying out a reliable moisture assessment test before the installation of the final floor finish is critical to avoid costly errors.

A Note on Psychrometric Charts

** Psychrometric charts are used to indicate graphically the parameters relating to the water content of the air. Typically, a psychrometric chart includes:

- Dry bulb temperatures shown on the horizontal axis, as vertical lines.

- Wet bulb temperatures shown as diagonal lines.

- Dew point temperatures and humidity ratio shown along the vertical axis, as horizontal lines.

- RH levels shown as curved exponential lines.

The intersection point of the dry bulb, wet bulb and dew point temperature readings with the nearest line of constant relative humidity indicates the RH level for the values specified.

Credits:

The psychometric charts created for this blog were made here:

http://flycarpet.net/en/psyonline

Sources:

- Sometimes it’s relative: The weather doctor http://www.islandnet.com/~see/weather/elements/humidity.htm

- Psychrometric charts and air conditioning. https://www.ohio.edu/mechanical/thermo/Applied/Chapt.7_11/Chapter10b.html

- Psychrometric chart use

http://web.uconn.edu/poultry/NE-127/NewFiles/psychrometric_inset.html - Observed Dew Point: University of Illinois http://ww2010.atmos.uiuc.edu/%28Gh%29/guides/maps/sfcobs/dwp.rxml

- Engineering Toolbox: Dry wet bulb dew point air

http://www.engineeringtoolbox.com/dry-wet-bulb-dew-point-air-d_682.html - A beginners Guide to Humidity Measurement http://www.npl.co.uk/upload/pdf/Beginner’s%20guide%20to%20humidity%20measurement%20%28draft%20for%20comment%29.pdf

- Tomorrows Flooring: Banish Bubbles in Vinyl. http://content.yudu.com/web/1jybr/0A1vxp9/TFJan15/flash/resources/17.htm

- Screeds Flooring and finishes: Selection construction and maintenance: CIRIA press

- Floors and Flooring: PW Pye and HW harrison

WHY SCREED TESTING CAN SAVE YOUR PROJECT TIME AND MONEY?

Download your free Practical Guide to Screed Testing here.